Use NI LabVIEW to best effect thanks to our experts

National Instruments' graphical programming system LabVIEW (Laboratory Virtual Instrument Engineering Workbench) is now used by thousands of businesses worldwide.

NI LabVIEW allows you to manage instruments, acquire measurement data, process and present results, and automate tests. A truly open platform for measurement system design and control, NI LabVIEW now plays a central role in testing laboratories, helping companies to rapidly put their products on the market.

Styrel, a LabVIEW centre of excellence for 20 years

With over 40 LabVIEW developers, most with CLAD, CLD and/or CLA certification, Styrel is probably the French company with the highest level of expertise in this environment. Over the years, we have gained unique expertise with LabVIEW, the fruit of our long-term partnership with National Instruments. These are some of the services we can provide for you:

- Audit and preliminary study

- Statement of requirements

- Prototyping

- Refactoring and rewriting code in object-oriented programming

- LabVIEW version migration

- Architecture specification and development (client-server, distributed, embedded, etc.)

- Integration of instruments and software management via LabVIEW

- Development of specific instrumentation drivers

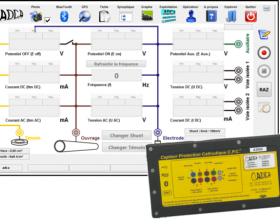

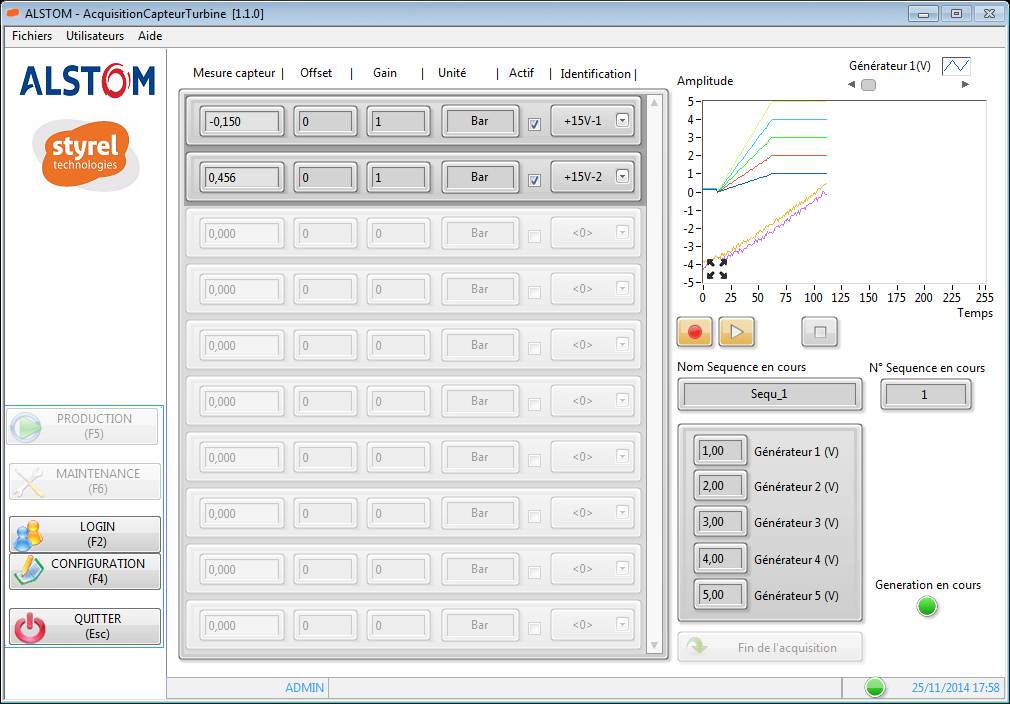

- HMIs, management and supervision

- Algorithm development and processing of signals (spectrogram, discrete Fourier transform, filtering, weighting window, etc.)

- Monitoring and control (open-loop control, closed-loop control, PID control)

- Real-time programming, FPGA programming

- Interfacing between different systems, communication protocols for automated systems, etc.

- Designing special instruments

- Curative or evolutive maintenance

- Retrofitting test benches under LabVIEW

- Standard or custom-designed LabVIEW training, first level or advanced

As technical support or as part of a fixed-price project, our engineers can work on the most complex and critical LabVIEW architectures, within tight completion deadlines.

What can you do with LabVIEW?

The goal of this National Instruments platform has never changed: to reduce development complexity for test and measurement (T&M) systems, and more generally for industrial and scientific systems.

LabVIEW does not merely provide engineers and scientists with a graphical approach for producing test benches, it offers unrivalled integration with all the data acquisition equipment from all manufacturers. It also combines in one environment all the tools enabling you to construct a complex autonomous industrial system: user interfaces, control panels, virtual instruments, triggering mechanisms, signal processing algorithms, statistical tools, real-time processing capabilities, simulation, etc.

INTEGRATION WITH NI EQUIPMENT

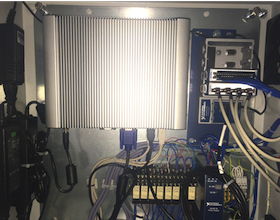

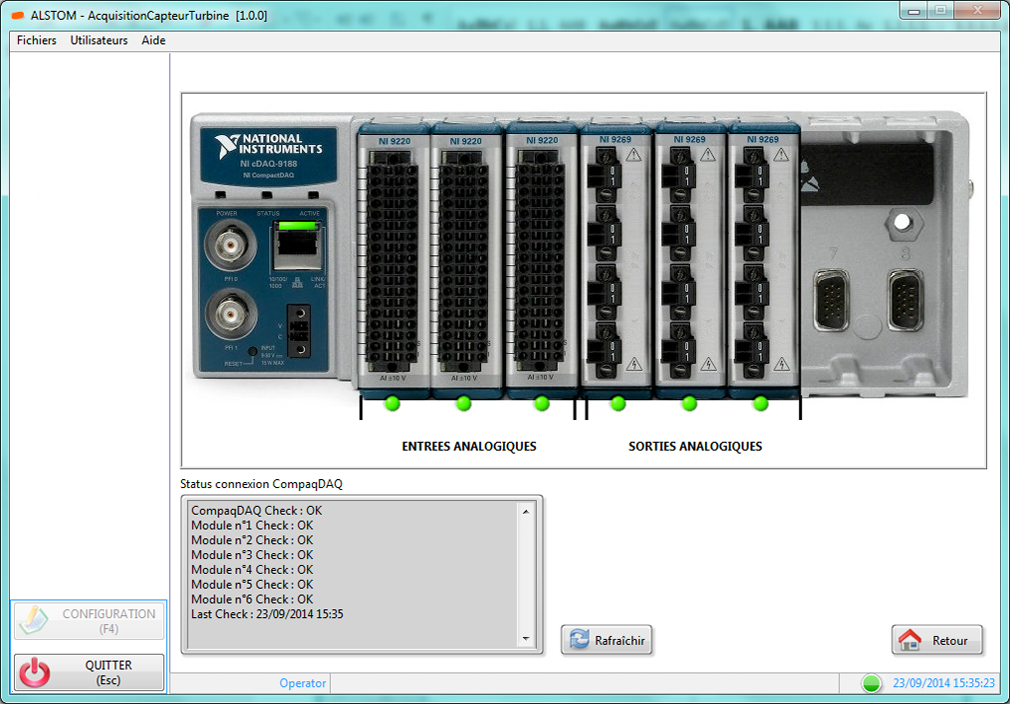

LabVIEW programmers can, of course, utilise the entire range of National Instruments equipment to construct their systems. In particular, they can incorporate cost-effective equipment such as NI DAQ USB boxes or NI DAQ PCI/PCI Express boards. They can also construct embedded systems based on the reconfigurable I/O platforms CompactDaq and CompactRIO. Lastly, LabVIEW programmers can benefit from the entire range of top-end PXI-format modular instruments.

INTEGRATION WITH ALL THE EQUIPMENT ON THE MARKET

In addition, there are now more than 10,000 different instrument drivers allowing you to utilise most of the equipment available off-the-shelf with just a couple of clicks. In our view that is the great advantage of this system, which allows engineers to focus on the measurements, not on the hardware/software interface problems.

DATA ACQUISITION TO SIGNAL PROCESSING

LabVIEW includes thousands of advanced analysis functions specially designed for engineers and scientists, who also benefit from detailed help files and comprehensive documentation. These powerful tools make it possible to perform advanced signal processing, frequency, probability and statistical analysis, curve fitting, interpolation, digital signal processing, etc.

DISTRIBUTED EMBEDDED APPLICATIONS

NI LabVIEW runs on various operating systems (Linux, Mac OS X, but mainly Windows), and can generate object code on these operating systems. But it also offers the option of deploying applications on real time platforms, embedded systems or FPGA reprogrammable components such as, in particular, the National Instruments RIO platform (CompactRIO, FlexRIO, and PXI RIO, SBRIO modules) that Styrel has thorough knowledge of.

COMPUTING POWER AND NATIVE PARALLELISM

Parallel programming is essential if you want to make maximum use of today's multi-core processors. With LabVIEW, you don't need to be an expert in parallel programming to make use of all its computing resources. LabVIEW automatically manages the allocation of threads and the parallel processes, so that the application executes across several cores when it is running on a multi-core processor. You can also use LabVIEW with other parallelised resources such as FPGAs, GPUs, and even remote virtual machines hosted on a Cloud infrastructure.

INITIATION MADE EASIER

To learn to use LabVIEW, there are a large number of tools and resources to help you construct your first system. In particular, we provide training courses led by an NI-certified trainer in Paris, Lyon or Rennes. We can also offer intra-company training courses tailored to your needs. Alternatively, you can learn about LabVIEW at your own pace with online courses. You don't need to start from scratch; there are examples of standard projects that work well for automating measurement and control systems.